by Teena Hughes, silk artist

First of all, let’s talk about the idea of “steaming silk”.

This is an essential process which has to happen when we use steam-set silk dyes. I paint on silk with really bright colours and the dyes that I use must be steam-set so that they will be vibrant and colourfast.

There are other types of silk dyes, so it’s important to read the instructions on the bottle from the manufacturer to find out whether or not they need to be steam-set at high-pressure, like the steam-set dyes which I use, or by using a different technique to set the colours to be permanent.

My silk dyes needed 3 hours of high pressure steaming to achieve the boldest colours and colourfast results.

I had been steam-setting my silk paintings on a stovetop horizontal steamer for quite a few years by this time, so I was very familiar with this whole process.

Over time I started to gain more clients, I needed to paint larger quantities of silk, and so I decided to invest in a tall, silk steaming machine, which was a large metal tube covered in protective material so that I wouldn’t burn my hands. It sat on top of an electrical base unit which sat on the floor, and where I could pour in the water and bring it up to boiling point.

- Boiling water of course bubbles crazily and can splash whatever is above it, so we need to bear this in mind before we start the story 🙂

Now we know what a silk steaming machine is, let’s talk about my Tale of The Rocketship Silk Steaming Disaster.

We need to go back in time to 1999, close to Christmas, when my American neighbour and student Laurie and I had become great friends and decided to paint up a storm (that’s “a lot” of silk for non-Aussies) in time for her overseas Christmas gifts and for my silk customers. I was ready to try out my new 6′ [2m] high silver silk steamer. It consisted of two parts:

- a base unit with electric element to plug into the power, and where the water would be

- the large metal/aluminium tube, or tower, part [approx 14 inches across and about 4 feet high] – which has some kind of padding/insulation wrapped around it and attached to it, so I can lift it up when it’s hot.

We had been painting for weeks on end, painting silk for Chrissy prezzies of all kinds and finally we were ready.

We had been painting for weeks on end, painting silk for Chrissy prezzies of all kinds and finally we were ready.

Out came the gigantic industrial roll of paper purchased at the paper factory, it took 2 of us to struggle to lift it up onto my worktable … whew! We very carefully lay all the silk scarves and metres of fabric on the white paper, keeping the silk away from the edges, roll up, pull the paper, roll up, pull the paper …

When the silk was all rolled (and it was a thick little roll, let me tell you!), it was time to suspend in the new “rocketship”.

I’d only ever used stovetop horizontal steamers so this was a new experience, and it was at this point I realised that there weren’t enough gadgets to actually dangle the wrapped silk anywhere (and the store where I bought the steamer did not provide any instructions at all!)

I’d been sold the steamer for a huge amount of money at that time (over $A400 in 1995), brand new, and received :

- (1) a unit which sat on the floor to boil water in,

- plus (2) the cylindrical shape made of aluminium and covered with silver padded outer shell.

- No lid.

- No rod to suspend the silk.

The ONLY instruction came on a piece of paper saying, “Suspend silk from rod, cover with towels or teatowel”.

Now if any of you actually have one of these steamers, you’ll know that those instructions were a little bit short of real!!

Researching silk steamers

I had a silk book from the USA which had photos of how to suspend the silk, so we pored over that for a while, dug holes into the top of the cardboard cylinder we had used for the length of silk, made a hook out of a coathanger and hung the whole lot on another piece of coathanger across the top of the steamer.

I had a silk book from the USA which had photos of how to suspend the silk, so we pored over that for a while, dug holes into the top of the cardboard cylinder we had used for the length of silk, made a hook out of a coathanger and hung the whole lot on another piece of coathanger across the top of the steamer.

We assembled it all, put towels and phonebook on top, set it for 3 hrs, and we took ourselves out to the balcony for a glass of wine.

As the sun was setting, I thought I hadn’t smelled that familiar “paper in high pressure steam” smell I’ve come to love over the years, so I checked the steamer ….

DISASTER HAD STRUCK!

I SCREAMED!

Laurie came running over as I lifted the cylinder up to reveal that our metres and yards of beautiful roll of silk wrapped in paper had BENT the coathanger bit in half (you could all see this coming … right?), and you guessed it — the whole roll was resting IN THE WATER … about 6″ deep.

We were shocked!

We were stunned!

We ran around like chickens with our heads cut off, we didn’t know what to do!

I felt so so guilty as Laurie had spent weeks on her silk and it was for gifts for all her family in the USA. I was grief-stricken that I’d ruined her Christmas.

Assessing the damage …

Well, when our tears dried up, we salvaged what we could, which was mostly the top two-thirds of the rolled silk, and yes, a lot of good silk was water-damaged that day, but I could never throw it away.

The good news is it taught us both a valuable lesson in engineering, and I’ve now perfected the silk-hanging-in-the-cylinder technique and have never had another accident. (Update – it’s 2018 and I’ve STILL never had another steaming accident like this!)

The ruined silk when dry had quite an unusual look to it, and ended up being used for lots of silk cards, bookmarks and other small projects so all was not lost.

This isn’t the water-marked silk 🙂 but we did make silk cards and bookmarks and other clever items with the water-damaged silk. PS – never throw silk away!

Silk bookmarks are another great way to use scraps of silk.

Moral of the story?

- Never use new equipment unless you’ve read all the instructions and researched the internet or books to get a better understanding of what you’re about to embark on!

- Never ever ever use new equipment on a big batch of new silk – always test one item first, make sure it works the way it should, and if it doesn’t, you’ve only lost one small item.

- Never throw silk away, you never know when it might metamorphose into a beautiful something-or-other …

Final Moral of the Story?

Final Moral of the Story?

TIP 1 :: Don’t use a coat hanger in your steamer to suspend silk on! This is where I went WRONG, because I had more than 4-5 scarves wrapped up, I had quite a few yards [metres] of silk which made the roll HEAVY.

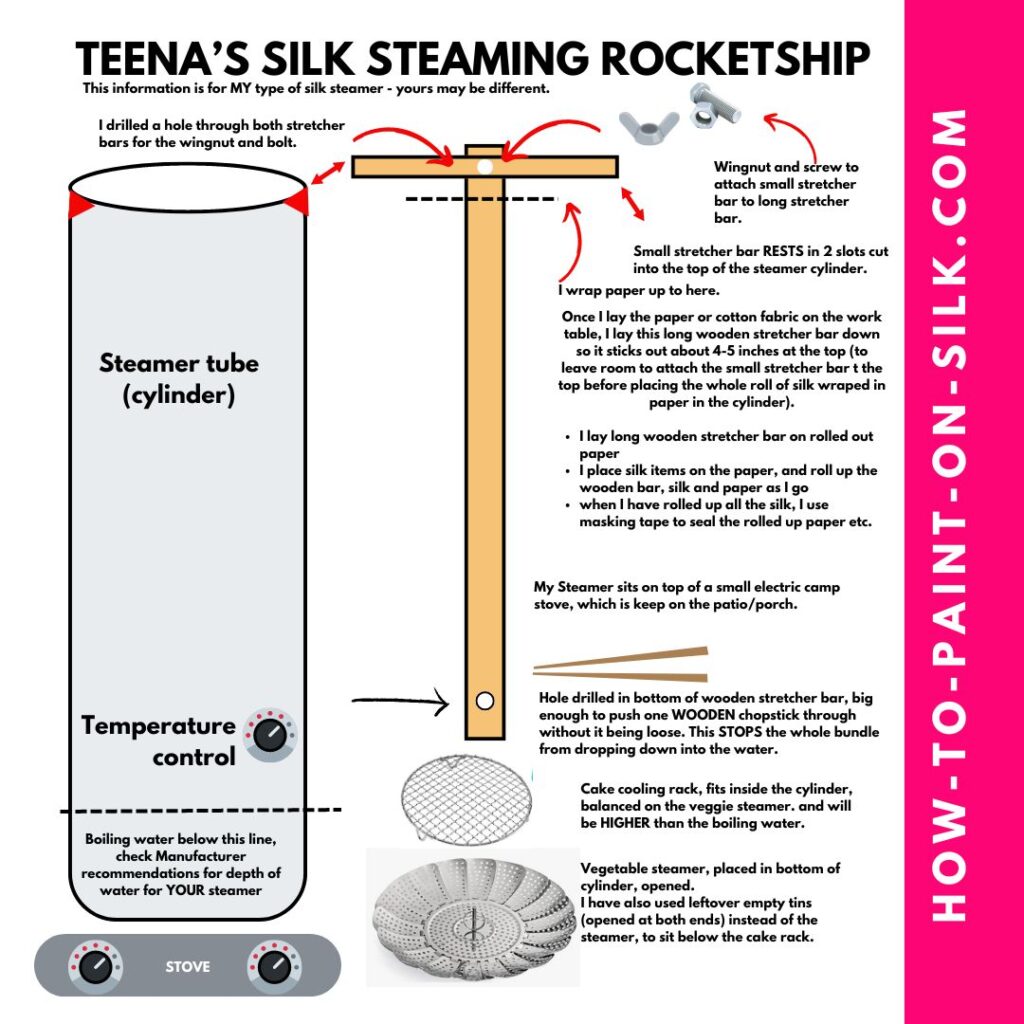

TIP 2 :: I now use a piece of wood which is wider than the cylinder (I actually use a Fredrix stretcher strip) which now rests in the two V-grooves at the top of the “rocketship” and is very sturdy.

TIP 3 :: I drilled a hole in the middle of it from which I hang the other piece of wood (also a long Fredrix stretcher strip) – instead of a cardboard cylinder- securely attached with a large screw and wingnut, with the silk and paper wrapped securely around it.

TIP 4 :: At the BOTTOM of the long wooden stretcher strip I drilled a hole big enough to push a WOODEN (not plastic!) chopstick through, but not big enough for it to fall out. I put the chopstick in the wood AFTER I roll the silk, and BEFORE I place it in the steamer tube.

There is maybe an inch on either side of the chopstick where it doesn’t touch the sides of the steamer.

This means that at no point will the wrapped silk ever touch the sides of the steamer, because the chopstick is horizontal and keeps the wrapped silk away from the sides.

TIP 5 :: The most important tip of all – how to stop the silk from falling in the water!

I bought a cheap cake rack [the kind you cool your cakes on when they come out of the oven], and I attached it to the top of the unit where the water resides. This meant that if the silk hanging above it fell, it would land on this rack … and never touch water.

I bet you have tons of stuff around the house to be ‘creative’ with when it comes to making your own steamer.

So go ahead – buy or make your own!

Have fun!

ATTENTION: IN THE IMAGE BELOW, THERE IS NO LID OR ANYTHING TO CLOSE OFF THE ROCKETSHIP!

- To keep the steam inside the rocketship, I placed a couple of pieces of the Fredricks. Stretcher bars wooden strips across the top of the steamer

- then I grab some old towels and I folded them so that they covered the entire circle of the rocketship top

- for good measure, I placed an old heavy “phone book” on top of it to hold the towels in place.

- Many of you reading this might be wondering what a “phone book” is 🙂 you don’t really need to know, all you need to do is put something heavy on top of the towels so that it can keep high-pressure steam happening inside for the hand painted silk. I did not want to have a tightly fitting lid on this – definitely not – because that would cause an explosion in my apartment! 🙂

Download the PDF >>

PS – Have you ever had a Silk Steaming Disaster?

I’d love to hear your story — please do write and let me know! Post in the Comments below, send me a message or pop over to the Facebook page.

Got questions about The Rocketship Silk Steaming Disaster?

I’d love to hear from you! Please do write a Comment below, or pop over to the Facebook page, Twitter page, or the Youtube Channel.

Have fun! Enjoy!

Teena Hughes

Not on my mailing list yet? Click the image to sign up so I can send you juicy silky tidbits 🙂

… or click here to Subscribe >>